HDD Reamer Repair: Minimize Downtime with Expert Maintenance

Need Your Reamer Repaired? Here’s What You Should Know

Reamers play a crucial role in Horizontal Directional Drilling (HDD) projects, helping to enlarge holes efficiently and accurately. But like any tool, reamers wear out over time and may need repair or maintenance. When faced with a damaged reamer, it’s essential to act quickly to minimize downtime and avoid costly delays. This guide will walk you through the importance of reamer repair and how to address issues to keep your HDD operations running smoothly.

Why Reamer Repair is Crucial for HDD Downtime Reduction

Reamers are subject to harsh working conditions, which can cause wear, tear, or even damage. When a reamer starts to underperform, it can significantly affect the efficiency of the entire HDD operation. Delays in reamer repair can result in prolonged downtime, which impacts productivity, increases labor costs, and pushes back project timelines.

Reamer repair is vital to HDD downtime reduction because it ensures tools continue to function effectively. Replacing or repairing damaged reamers as soon as possible can minimize delays, reduce unnecessary costs, and maintain project momentum.

Signs Your Reamer Needs Repair

Recognizing when a reamer requires repair is crucial for preventing unexpected issues during the drilling process. Some common signs include:

- Increased vibrations or noise: If your reamer is producing unusual vibrations or noise, this could indicate that the tool is damaged or worn.

- Uneven or inconsistent drilling: A reamer that fails to create smooth, consistent boreholes might have damaged tooth, weld lines or wear on other components.

- Excessive wear or cracking: Check the reamer for signs of physical damage like cracks or worn edges, which could compromise its performance.

- Reduced efficiency: If the drilling process seems slower or more difficult than usual, this might be a sign of tool degradation.

If you notice any of these signs, it’s time to assess whether repair is necessary.

Choosing Between Repair and Replacement

When your reamer starts to show signs of damage, one of the first decisions you’ll face is whether to repair or replace it. Here’s a breakdown to help you decide:

- Repair: Repairing a reamer is a cost-effective option if the damage is minimal and can be fixed by replacing certain components, like the carbide cutters or the welding lines. It’s also a great way to extend the lifespan of an otherwise high-quality tool.

- Replacement: In cases of severe damage, replacement may be the better option. For example, if the reamer has deep cracks or extensive wear that cannot be fixed cost-effectively, purchasing a new one may be the best long-term solution.

Regardless of your decision, it’s essential to factor in the cost of downtime. If repairing the reamer can minimize downtime and costs, it’s worth considering. However, if a new reamer offers better performance and longer life, it might be a better investment.

Steps to Repair Your Reamer

Reamer repair can vary depending on the level of damage and the tool itself. Here are some general steps involved in the repair process:

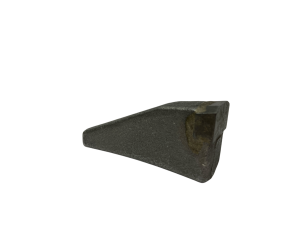

- Inspect the Damage: Start by carefully inspecting the reamer to identify any visible cracks, chips, or excessive wear on the weld-on teeth or body.

- Assess the Severity: Determine whether the reamer can be repaired or needs to be replaced. This will depend on the extent of the damage and the cost-effectiveness of repair.

- Replace Worn Parts: If your reamer’s teeth or other components are worn out, replacing them with high-quality parts is essential. This can restore the tool’s functionality and performance.

- Welding:A common repair involves welding new lines to restore the reamer’s ability to smoothly enlarge the borehole. This process helps extend the reamer’s lifespan and ensures optimal performance.

- Reassemble and Test: Once the repair or replacement is complete, reassemble the tool and measure if the teeth has been right positioned and if all nozzles and other fluid components are well installed.

By staying proactive with your tool care, you can extend the lifespan of your reamers and reduce the frequency of repairs.

Trust HDD Drilling Tools for High-Quality Reamers and Repairs

At HDD Drilling Tools, we understand the importance of maintaining high-performance equipment. Our Dutch-made reamers are designed for durability and precision. Whether you need a replacement part or full reamer repair, we offer high-quality products and services to keep your projects running smoothly. With the right tools and proper care, you can avoid costly downtime and maximize productivity.

If your reamer is showing signs of wear or damage, don’t wait until it causes a delay. Reach out to us for expert repair services or high-quality replacements that will keep your HDD operations efficient and cost-effective.

Extra Tip:

After repair and maintenance, make sure to flush the reamer thoroughly. This ensures that no debris or particles are left inside that could potentially block the nozzles when the reamer is put back into operation in the field. Proper cleaning is essential for maintaining optimal performance and preventing any further damage during use.

Need More Information?

Contact our team to discuss your drilling requirements or to learn more about our services.

Contact Us